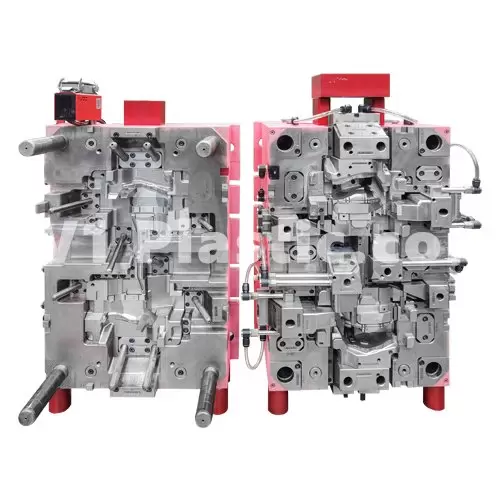

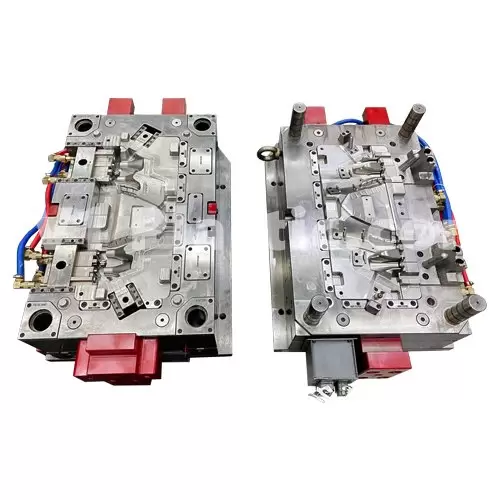

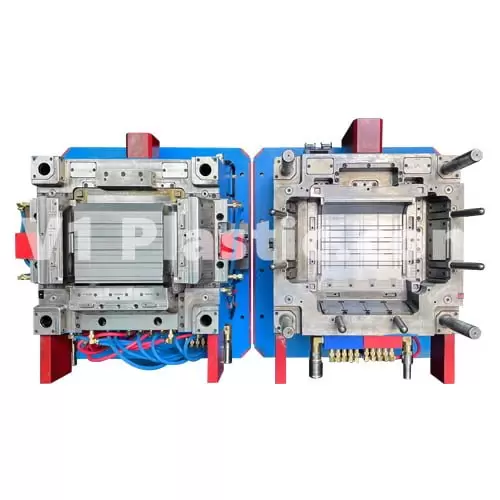

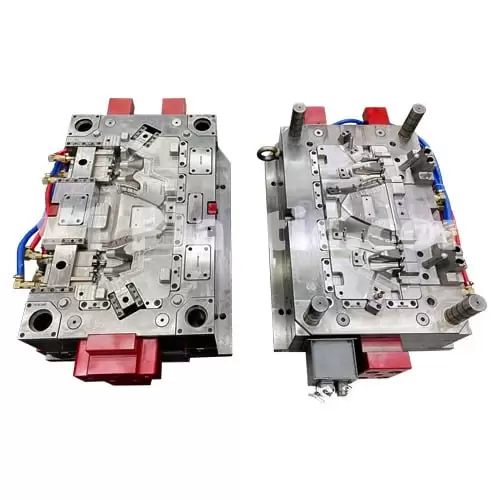

Plastic Injection Mould Toolmaking

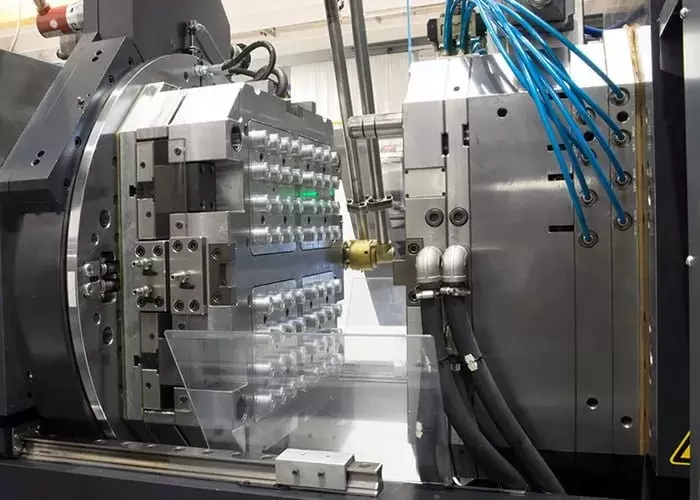

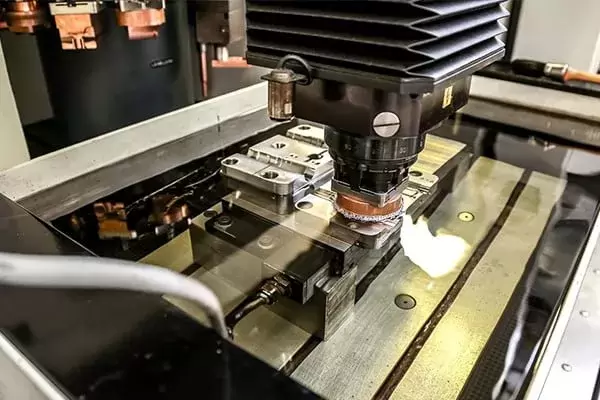

Our Plastic Injection Mould Toolmaking solution is a high-quality solution that specializes in manufacturing plastic injection molds for various plastic products. The solution involves the use of advanced CAD/CAM software for designing and developing the molds and high-precision CNC machines for manufacturing to ensure accuracy and reliability. The main goal of this solution is to provide efficient, precise, and reliable molds that meet the customers’ requirements for product quality and production efficiency.

V1 Injection Molding Services

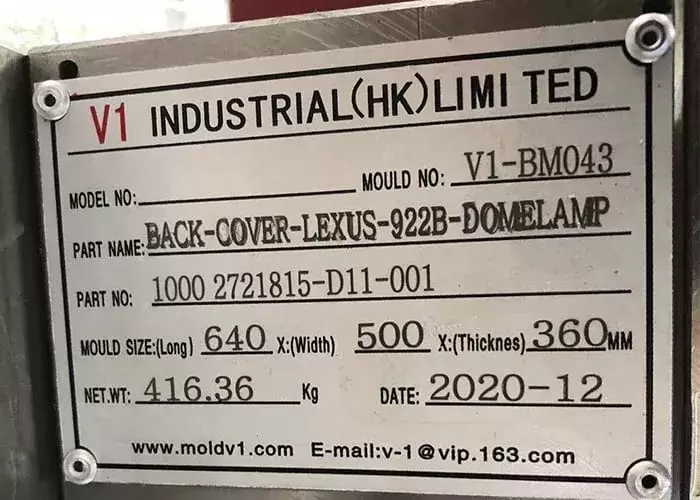

Our in-house plastic injection mould toolroom in Chang’an provides us with complete control over each phase of manufacturing, from initial tool design to final program sign-off in the customer’s production environment. We efficiently support each significant milestone from start to finish, ensuring timely completion.

With our own technical center in China and strategically placed satellite offices around the world, we can fulfill all your export plastic mould tooling requirements and provide on-demand support. This ensures that you are always in touch with the program activity on the ground.

This Can Be Secondary Heading

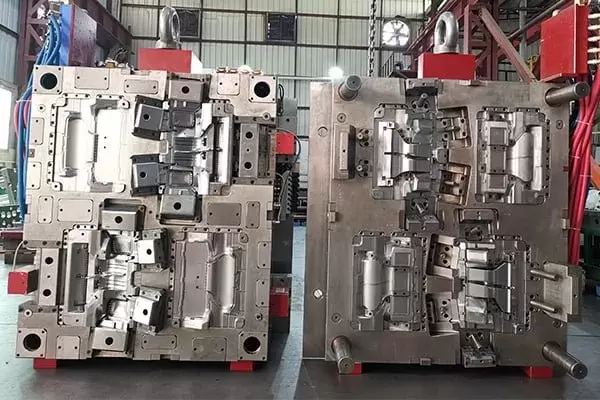

Mold Tooling

We have extensive experience working with both P20 steel and aluminum to create molds that meet the specific needs of our clients. Our team of experts will work with you to ensure that the molds are designed to produce high-quality products with tight tolerances.

Plastic Injection Molding

Our network of reliable suppliers allows us to scale production from a few hundred to millions of units. We use the latest injection molding techniques and equipment to ensure that our products meet the highest quality standards.

Post Processing

We offer a wide range of post-processing services, including ultrasonic welding, overmolding, screen printing, and more. Our team has the expertise to ensure that your products are finished to the highest standards.

Box Assembly +Packaging

Our services don’t end with manufacturing. We also offer box assembly and packaging services to ensure that your products are properly assembled, packaged, and ready to be shipped to the end user.

V1 Injection Molding Capabilities & Specifications

Reliability, quality and value for money are the hallmarks of our Plastic Injection Moulding service with expertise plastic moulders in the China.

Facility

- High-end equipment with ongoing improvements

- Capacity: up to 50 injection mold tooling sets per month

- Mold standards: DME (USA), Hasco (Germany) & DAIDO (Japan)

- Two locations: Chanan or Wuhan , China ~30,000 square mete

Capabilities

- Shot Capacity: fractional to 105oz

- Tolerance: +/- 0.005-0.01mm.

- Number of cavities: 1 - 16

- Mold size: miniature to automotive sized parts

- Mold weight: fractional to 14 tons

- Clamping force/ press size: 50T - 1000T

- Minimum thickness: 0.3-0.5mm (also determined according to different products/materials)

Materials

- All thermoplastics & elastomers

- Acrylonitrile butadiene styrene (ABS)

- Polyethylene

- Polycarbonate

- Polyamide (nylon)

- High impact polystyrene

- Polypropylene

- Various textures and colors

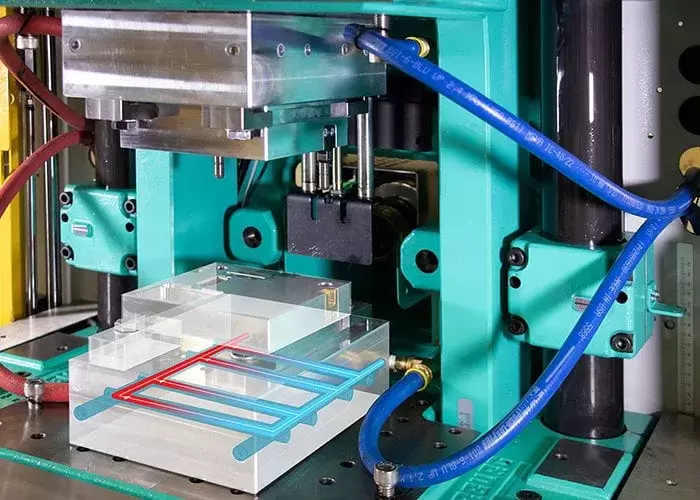

- Precision transparent products

Features & Add-ons

- Anti-UV

- Fire retardants

- Talc

- Antibacterial agents

- Plasticizers

- Other additives

- Chrome finish

Secondary Operations

- Box-build assembly

- Electroplating

- Hydro-dipping (water transfer)

- Pad printing

- Screen printing

- Laser etching

- Overmolding

- Insert molding

- Ultrasonic Welding

- Molded in color

- Molded in symbols

- Hot stamping

- Internal and external Threads

- Metal stamping

Plastic Injection Molding Gallery

We are proud of our long track record for success within our plastic injection moulding service.

We can design and manufacture a wide range of tool manufacturing and injection moulding in any type of thermoplastic polymer.

Our experienced and skilled teams offer a complete, bespoke manufacturing service across three shifts, 24/5, to reduce lead times and ensure customer satisfaction.

What Is Injection Moulding?

Injection moulding is a manufacturing process used for producing plastic parts in large quantities. It involves injecting molten plastic material into a mould cavity under high pressure and allowing it to cool and solidify. Once the part has solidified, the mould opens, and the part is ejected. Injection moulding is used to manufacture a wide range of plastic products, from small components to large automotive parts.

The Main Advantages of Plastic Injection Moulding:

- High Efficiency and Cost-Effectiveness: Injection moulding allows for the production of large quantities of parts quickly and cost-effectively, making it an ideal choice for mass production.

- Design Flexibility: Injection moulding offers a high degree of design freedom, allowing for the production of complex and intricate shapes with ease.

- Consistent Quality and Precision: Injection moulding produces parts with a high level of accuracy and consistency, resulting in high-quality products.

- Wide Range of Material Options: Injection moulding can use a variety of plastic materials, including engineering-grade plastics, to meet specific application requirements.

- Reduced Waste: Injection moulding produces minimal waste, as any excess plastic material can be recycled and reused.

- Automation: Injection moulding can be highly automated, reducing labor costs and increasing efficiency.

- Versatility: Injection moulding can produce parts in a wide range of sizes, shapes, and complexities, making it a versatile manufacturing process.