Plastic Injection Molding Services

- Rapid Lead Times

- 100+ Materials for Choosen

- Strict Quality Control System

- On-demand Production

Certifications: IATF16949:2016 | ISO9001:2015|ISO 14001:2015

V1 is a Professional injection mold factory

V1 Mold Technology Co., Ltd. is a leading plastic injection molding company with over a decade of experience. We specialize in helping you overcome common challenges like insufficient capacity, uncertain design capability, unstable product quality, and untimely delivery. Our expertise spans across various industries, including automotive, consumer electronics, and medical. Our team of 50+ professionals, including designers, programmers, operators, and quality supervisors, work seamlessly to deliver exceptional results. With a track record of successfully serving hundreds of customers worldwide, we have earned consistently positive feedback. Trust us to bring your vision to life with precision and efficiency.

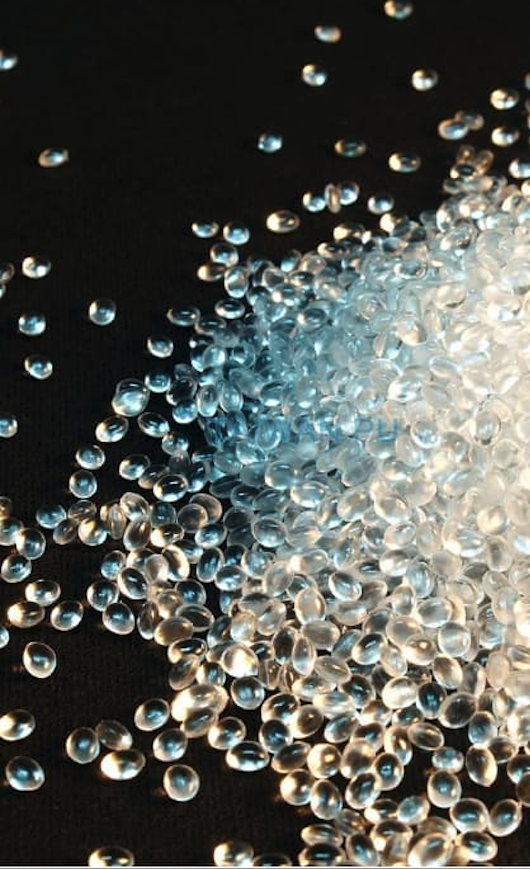

Injection Molding Materials

We provide an extensive selection of high-quality materials to meet our customers' diverse needs, ensuring superior product performance. With our vast network, we have the capability to source thousands of materials based on your specific requirements. Additionally, our expertise allows us to provide accurate machining quotes for over 50 metals and plastics, enabling precise cost estimation and seamless project planning. Trust us to deliver exceptional quality and comprehensive material options for your manufacturing projects.

Tooling Materials

Before starting injection molding for low or high-volume production, high-tolerance CNC machined tooling is requisite. The materials used for CNC tooling are:

Tool Steel: P20, H13, S7, 718, 718H, 738, NAK80, S136, S136H

Stainless Steel: 316, 301, 303, 304, 420, NAK80, S136, 316L

Aluminum: 6061, 5052, 7075

Plastic Materials

With an extended range of plastic materials, you can choose what fits your needs perfectly. Each material has qualities that include heat resistance, impact strength, wear resistance, and many more.

- Impact resistant: ABS, PMMA, PVC, PE, PC

- Wear-resistant: POM, PEEK, UHMW

- Dimensional stability: PBT, ABS, HIPS, PPS

- Chemical resistance: PEEK, PP, PBT, PA, PE, LDPE

- Rubber like: TPU, TPE, Silicone

- Cost-efficient: PP, HDPE, LDPE

- Cosmetic: ABS, PC, HIPS

Additives and Fibers

We incorporate additives and fibers to enhance the quality and esthetics of standard plastic materials. The process increases the functionality and performance of the molded product.

- UV absorbers

- Colorants

- Glass fibers

- Flame retardants

- Plasticizers

Why Choose Us

How To Work With Us

While the plastic injection molding process may appear straightforward, it actually involves many critical parameters that must be closely controlled to ensure the quality and consistency of the plastic components produced. Trust our team of experts to meticulously manage every aspect of the molding process to deliver exceptional products that meet your exact specifications.

Submit Request

To receive a complimentary quote, simply provide us with a product description and technical drawing with your request. If you don't have a technical drawing available, don't worry. We also offer reverse engineering services to help bring your vision to life. Trust V1 to deliver exceptional products that meet your exact requirements.

DFM & Quotation

At V1, we understand the importance of timely communication. That's why our typical response time is within 24 hours. Please note that the communication process may require ongoing discussions, but rest assured that the entire process is completely free of charge. Trust us to provide you with exceptional service and support throughout the entire process.

Mold-Making

At V1, once your design has been approved, we will begin the mold-making process for your plastic parts. Our team of experts utilizes the latest technology and equipment to fabricate a high-quality mold that meets your exact specifications. Trust us to deliver exceptional results that meet your expectations.

Injection Molding

Once the mold is ready, V1 will commence the injection molding process. Our skilled technicians will utilize the mold to create high-quality plastic parts that are consistent in shape and size. We perform quality control checks throughout the process to ensure that your products meet the highest standards of quality and excellence. Trust us to deliver exceptional results that exceed your expectations.

The Plastic Injection Molding Process

1.Clamping

The core and the cavity are the two main pieces of an injection mold. In the first step, during clamping, these two parts of the mold will be extruded and fit together by the machine.

2. Injection

The plastic pellets are fed to the part of the barrel and loaded into the main cylinder, where they are heated at high temperatures to a liquid. The plastic liquid will be injected into the mold cavity when mixed in good condition.

3. Dwelling

Next is the dwelling phase, where the melted plastic is filled to the entirety of the mold through pressure. The pressure is applied directly to the mold such that the liquid fills all mold cavities, and the product comes out accurately and is identical to the mold.

4.Cooling

This process step allows the time needed for the mold to cool. If this step is performed too hastily, the products may stick together or become distorted when demolding.

5. Mold Opening

This is the opposite process of clamping. In this step, a clamping motor slowly opens the two parts of the mold to make for the safety and stability.

6. Ejection

After the mold is opened, the ejector pin will push the cooled product out of the mold cavity according to the design position, so that a basic product is completed.

What Is Plastic Injection Molding?

Plastic injection molding is a highly efficient and effective manufacturing process that can quickly produce intricate geometrical shapes for custom parts and products. It is the preferred process for companies looking to produce repeatable parts with strict mechanical requirements. The process involves filling a mold tool with liquid plastic resin under high pressure. The tool may have a single cavity or hundreds of cavities to produce unlimited numbers of parts. Trust V1 to deliver exceptional results using the latest injection molding technology.

Benefits Of Plastic Injection Molding

- Rapid production of large volumes:

Once the process is set up and tested, injection molding machines can produce thousands of items quickly and efficiently.

- High surface quality:

Injection molding can produce high-quality parts with consistency, strength, and detailed features.

- Cost-effectiveness:

Once the mold is built, the cost of production per component is relatively low, especially for high-volume runs.

- Flexibility:

Manufacturers can choose the mold design and type of thermoplastic, allowing them to produce a variety of components, including complex and detailed parts.

- Consistency and repeatability:

Injection molding produces precise and accurately identical parts that are consistent and repeatable, making it an ideal process for producing thousands to millions of parts.

Trust V1 to deliver exceptional results using the latest injection molding technology, providing you with the quality and consistency you need for your products.

Find High-Quality Plastic Injection Molding Services?

F.A.Q.

Injection molding is a unique process of manufacturing products by injecting molten plastic resins in the mold cavity to produce desired products. This process is widely used in the plastic product manufacturing industry for the high-volume production of complex parts with precision. It offers high repeatability, efficiency, and low cost throughout the process.

With the injection molding process, you can typically manufacture products with complex geometrics and tight tolerance consistently. It is consistent with a diverse range of resin materials and colors, offering flexible and fast production.

However, it demands careful operating and handling, such as temperature and pressure setting of molten material, to ensure premium quality and reliability of final products.

Since it is a versatile and advantageous process for many applications, several high-grade industries use it to produce high-quality and durable molded products.

Some of the common industries that leverage injection molding are as follows;

- Automotive Industry:Injection molding is the ideal option for the automotive industry as it offers precision for highly-complex parts. The automotive industry uses injection molding to craft specific car parts such as bumpers, grills, dashboards, car panels, and door handles.

- Aerospace Industry:It is another common industry that widely utilizes the injection molding for precise parts manufacturing. The process is used explicitly for making lightweight and functional parts. It manufactures aircraft parts, like enclosures, winglets, structural components, turbine housing, and panels.

- Medical Industry:Medical industry demands accurate manufacturing of small and high-grade sensitive parts. From complex medical devices to small equipment such as syringes, drip valves, and containers are constantly made with injection molding process for enhanced durability and sensitivity of medical products.

- Consumer Product Industry:The injection molding method for manufacturing plastic products is also common in the consumer product industry. It is used for manufacturing kitchen gadgets, toys, household device enclosures, and musical instruments. The process is compatible with thermoplastics and thermoset material; thus, a cost-effective option for the consumer product industry.

It is a process used for manufacturing plastic products. We heat the plastic material to change it into molten and then pour it around the mold. Molten plastic then solidifies and transforms into the required plastic product. It is quite a convenient method for making complex plastic parts that demand high precision and detailing.

Injection molding is commonly used for mass production as it is a cost-efficient and relatively faster process than other plastic molding methods. Once the mold is set up, it can be reused up to millions of times to produce identical parts with consistency.

It has been widely used in industries aiming to achieve high repeatability and accurate plastic products.

1: Requirements Analysis Planning

In the first step, we understand the client’s requirements and design the blueprints accordingly. We analyze the requirements, such as mold design, material to use, production capacity, and resources, to plan the entire production process.

2: DFM Report Analysis

We provide free detailed DFM reports enabling clients to understand mold design feasibility in the production phase. Design for manufacturability report allows the clients to determine if the final product meets their requirements.

3: Mold Production

After the approval of the DFM report, the next step is mold production. Initially, during mold production, a Tooling Schedule form is provided to them for monitoring the production cycle at any time.

4: Free Sample Testing

The fourth step is the testing phase, where we provide free sample testing to the clients with a detailed report of the production phase. The testing phase allows us to cater to any issues we encounter during production at an early stage.

5: Mass Production:

After a successful testing phase and satisfactory client remarks, we began the mass production of plastic molded products. Our expert teams inspect the process comprehensively to ensure the standard quality of products.

6: Inspection and Mold Saving:

We conduct a thorough inspection of produced parts to make sure every part is error-free and perfectly functional. For future production, we clean and preserve the molds in a safe environment.

One thing that is closely considered during the injection molding process is tolerance. However, there is no standard tolerance range specified for molded products. It entirely depends on the mold design, geometric complexity, and part size. Here is a typical tolerance range of common molded parts;

Parts Types | Tolerance (Inches) |

Simple Injection Molded Parts | +/- 0.002 to 0.005 |

Geometrically Complex Parts | +/- 0.001 to 0.003 |

Large molded parts | +/- 0.005 to 0.010 |

There is no MOQ at Kemal. Whether you need a single part or mass production, we accommodate customers on all order quantities. However, pricing may vary on order quantity. It will be cost-effective in case of bulk orders.

The injection molding process cycle depends on the product’s size, design complexity, and specifications. Manufacturing molded parts in advanced injection molding machinery typically take a few seconds to two minutes. However, complex parts take demand longer cycle time than simple parts. Moreover, the required manufacturing time also depends on the complexity of the finishing and assembling process.

The injection molding process cycle depends on the product’s size, design complexity, and specifications. Manufacturing molded parts in advanced injection molding machinery typically take a few seconds to two minutes. However, complex parts take demand longer cycle time than simple parts. Moreover, the required manufacturing time also depends on the complexity of the finishing and assembling process.

There are several types of processes that injection molding solution companies use for a wide range of applications. Here are some common types of injection molding processes;

- Plastic Injection Molding (Cold-shot & Hot-shot)

- Metal Injection Molding

- Overmolding

- Die-Casting Molding

- Insert Molding

- Gas-assisted Molding

- Micro Injection Molding

- Multi-Shot Injection Molding

An injection mold lasts hundreds of cycles to millions without repair and replacement. It mainly depends on the maintenance, cleanliness, SPI rating, and quality of the mold. If the mold is cleaned and stored under favorable conditions, its lifespan will be extended.

At Kemal, we follow a rigorous process for cleaning and preserving molds to ensure longevity and reusability. We store molds under ambient conditions for future production cycles.

Plastic injection molding service is achievable in a suitable manufacturing facility with advanced machinery and expert designers. Chinese injection molding companies like Kemal are known for fast production and precision molded parts.

With our own factory, we provide complete injection molding services from mold manufacturing to mass production in one place. For free quotes and rapid prototyping, contact us.