Fiberglass Molding

Introduction

Here is everything you will need to know about fiberglass molding available on the internet.

You will learn:

- What is Fiberglass Molding?

- How Fiberglass Molding is Made

- Types of Fiberglass Molding

- Uses for Fiberglass Molding

- And much more...

Chapter One – What is Fiberglass Molding?

Fiberglass molding is a method for forming complex and intricate parts using fiberglass resin. Though there are several reasons for producing parts and components from fiberglass, the most pressing reasons are the cost of the materials, ease of production, durability, and replicability.

Regardless of what you wish to copy using fiberglass, it starts with a pattern, which is an exact representation of the final product. A wide variety of materials are used to produce the pattern. The benefit of the pattern is how it can be shaped to include the finest refined details and most intricate designs.

Fiberglass molded parts are strong, sturdy, long lasting, and a cost effective solution to component production. Products produced using fiberglass molding can be completely finished right out of the mold or have a paintable surface.

Chapter Two – Uses for Fiberglass Molding

Fiberglass molding is an inexpensive method for the production of durable and lasting products and parts. Aside from its cost effectiveness, fiberglass is stronger and sturdier than certain metals, non-conductive, can be formed into intricate and complex shapes, and is chemical inert. There is a long list of industries that use fiberglass to produce their components from leisure products to ones used for passenger aircraft.

Uses for Fiberglass Molding

Fiberglass Storage Tanks

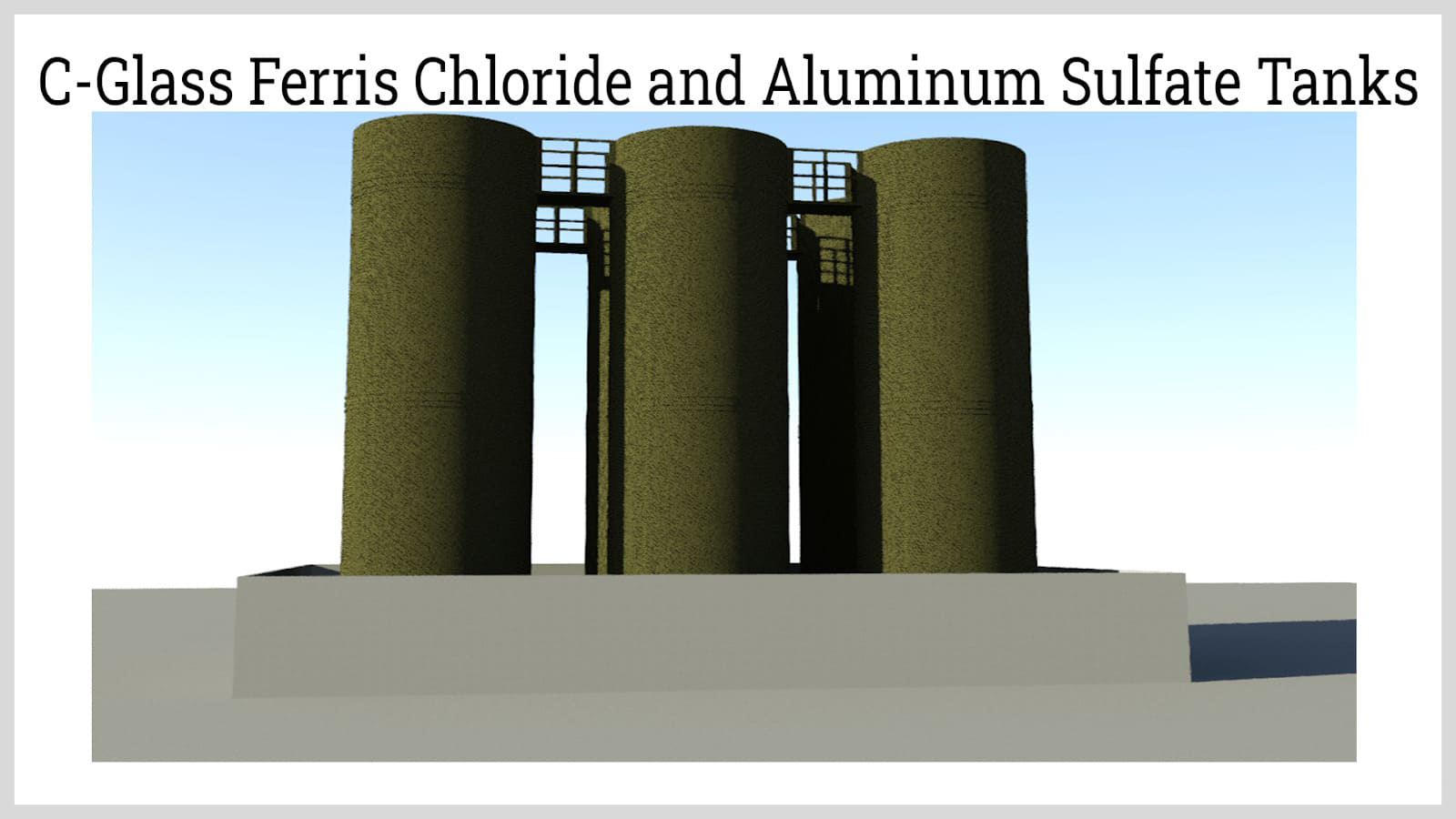

Fiberglass storage tanks can be above or below ground and can be used for rainwater harvesting, oil field storage, liquid fertilizer, water treatment, and irrigation water. They come in a wide variety of sizes from ones that can set in a backyard up to ones of over a 1,000,000 gallons. They can be shaped, fitted, and customized to fit any application.

Storage tanks come in several different varieties, which include horizontal, upright, cone bottomed, and open topped.

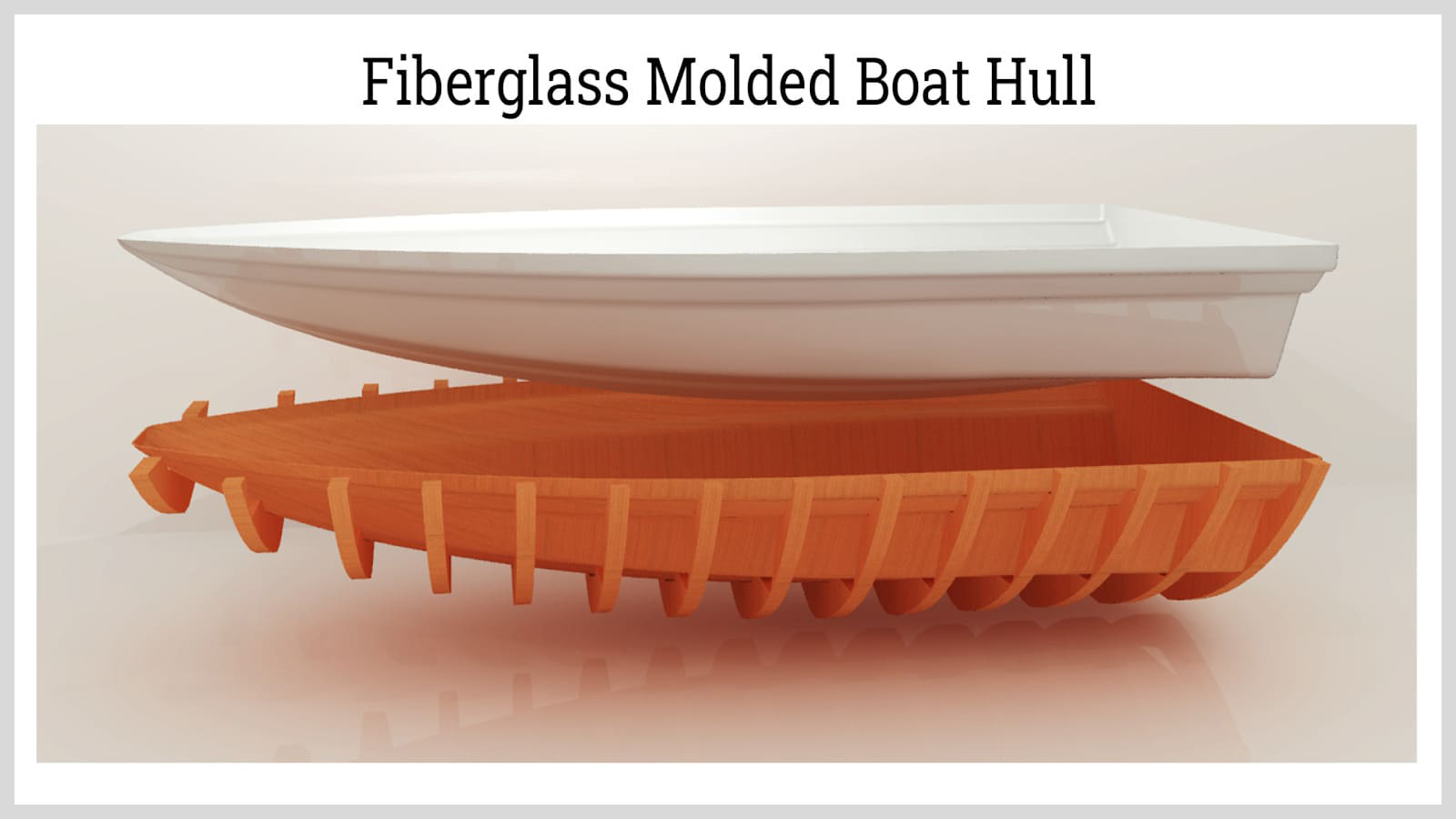

Fiberglass Boat Building

Modern boat building has moved away from using wood, steel, and other materials. Every part of today‘s boats is made from molded fiberglass that is specially chosen to fit the type of boat with polyester being the most commonly used.

The process begins by spraying a female mold with gelcoat to which fiberglass cloth is applied. A resin is coated or wets out the fiberglass. Once the resin has cured, the boat or part of a boat is ready for assembly.

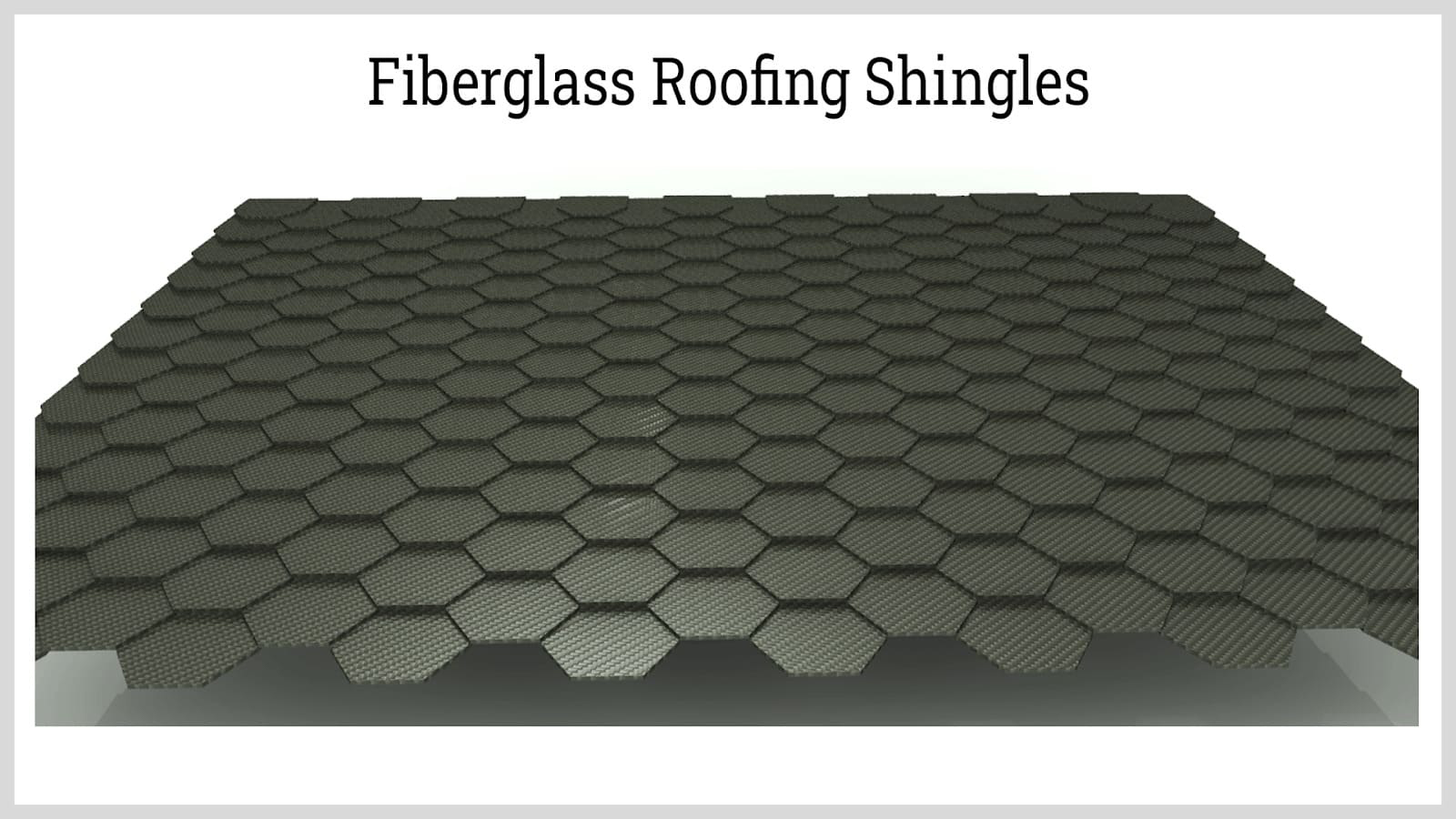

Fiberglass Home Building Materials

Fiberglass is widely used in the construction of homes as material for facades as well as roofing material. Architects used fiberglass due to its ability to be easily shaped and configured to fit the needs of a project. Other uses for fiberglass as a building material are as a shade or awning since fiberglass is a good method for sealing and protecting structures.

Fiberglass Pipes

Fiberglass reinforced pipes (FRP) are used in trenchless installation of pipelines. The many factors that make fiberglass piping ideal is its lightweight, resistance to temperature changes, strength, and resistance to corrosion or chemicals. Their low maintenance and ease of installation make them an ideal choice as piping material. It can be used for trenchless installations due to its exceptionally smooth outer finish.

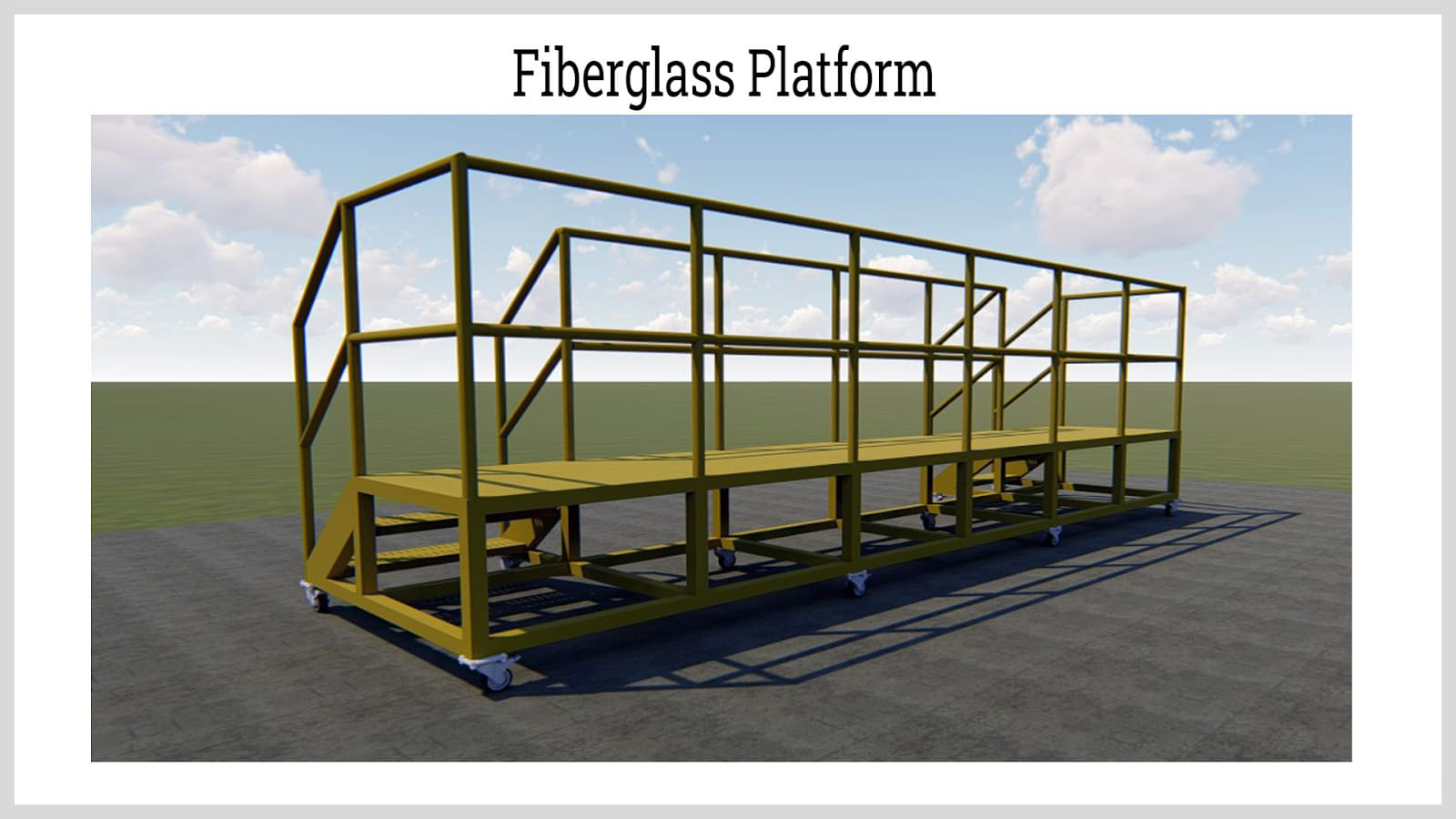

Fiberglass Platforms

Its sturdiness, durability, strength, and corrosion resistance make fiberglass ideal for the manufacturing of interior and exterior platforms. A necessity for platforms is stability since they have to be able to withstand rugged use. Since fiberglass is very flexible and can be shaped into any dimensions, it is the perfect material for the construction of platforms.

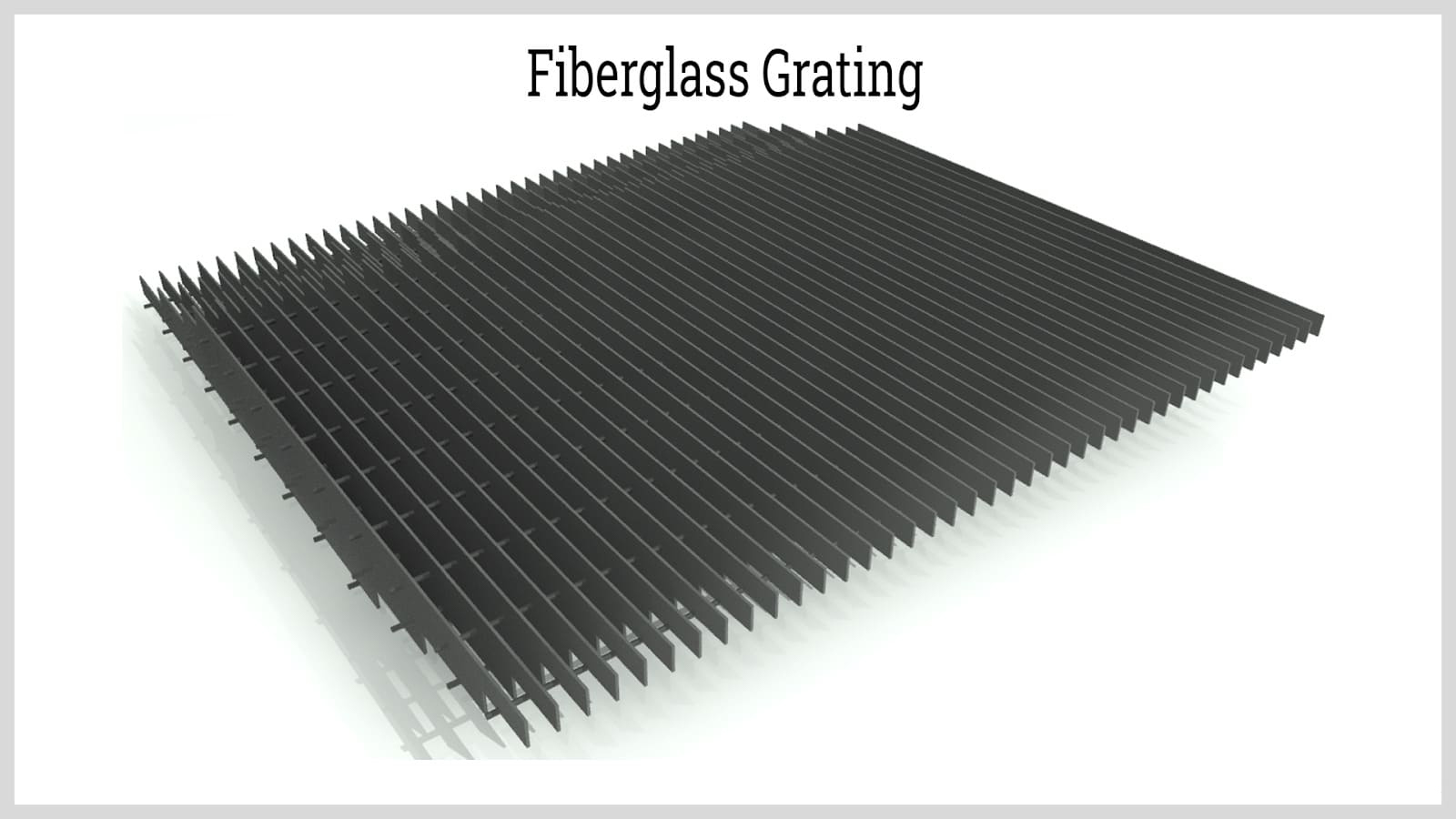

Fiberglass Grating

Molded fiberglass grating is impact resistant and provides excellent traction. Like all other fiberglass products, fiberglass grating is corrosion resistant, lightweight but sturdy, nonconductive, and nonmagnetic. The fact that it is nonconductive and nonmagnetic makes it ideal for use in manufacturing and production environments.

Fiberglass Doors

Fiberglass doors are a perfect replacement for mental or steel doors. They provide a tight seal and are non corrosive. The home building industry no longer installs wood doors since they tend to warp, rot, swell, and shrink. Fiberglass doors do not dent, splinter, and are energy efficient.

In the case of industrial environments, fiberglass doors are far more capable of withstanding the hazardous and stressful conditions found in manufacturing.

Fiberglass Sinks

A new addition to modern homes is the fiberglass sink, which is very durable and long lasting. Unlike other sinks, fiberglass sinks are stain resistant and easy to clean. They provide a very neat and clean appearance and are difficult to damage.

Fiberglass sinks can be shaped and formed to fit any configuration whether it is a corner sink or one with a drain board and can be easily installed and mounted.

Fiberglass Furniture

Office chairs and outdoor furniture are made from fiberglass because of its durability, aesthetic appearance, and design. Unlike other furniture manufacturing processes, fiberglass furniture is low maintenance and able to take continuous and stressful wear. In office environments, it can withstand the constant traffic, being moved, and everyday continuous use.

Fiberglass Auto Parts

With the rising need to lighten vehicles for the purpose of increasing gas mileage, fiberglass molded components and parts have become essential in automobile design and manufacturing. Several parts of a car's body such as hoods and various panels are molded and produced from fiberglass. The ability of fiberglass to be molded into a wide variety of shapes makes it the perfect tool for engineers and designers.

Leading Fiberglass Molding Manufacturers and Companies

-

All Plastics and Fiberglass, Inc.

-

Janco Engineered Products

-

Diamond Fiberglass Fabricators

-

Progressive Fiberglass Fabricators, Inc.

Chapter Three – How Fiberglass is Made

The first form of fiberglass was produced in the middle of the first industrial revolution. The form that we know today was created by a researcher at Owens-Illinois, which later became Owens Corning. The name that Owens Corning patented was fiberglas with one "s". It was an accidental discovery when a jet of compressed air was directed at molten glass, which produced fibers.

From its original discovery to be used as insulation, fiberglass has grown into a widely used material that can be shaped into limitless products. The modern process is more technical than mechanical and uses a variety of polymers and other materials to produce what is referred to as fiberglass.

How Fiberglass is Made

Fiberglass is made from glass fibers. The types of glass fibers are separated by their geometry, which are continuous and discontinuous. Continuous fibers are like yarn such as cotton or wool. The existence of glass fibers can be traced back to the Renaissance when it was used as decorative material for art works.

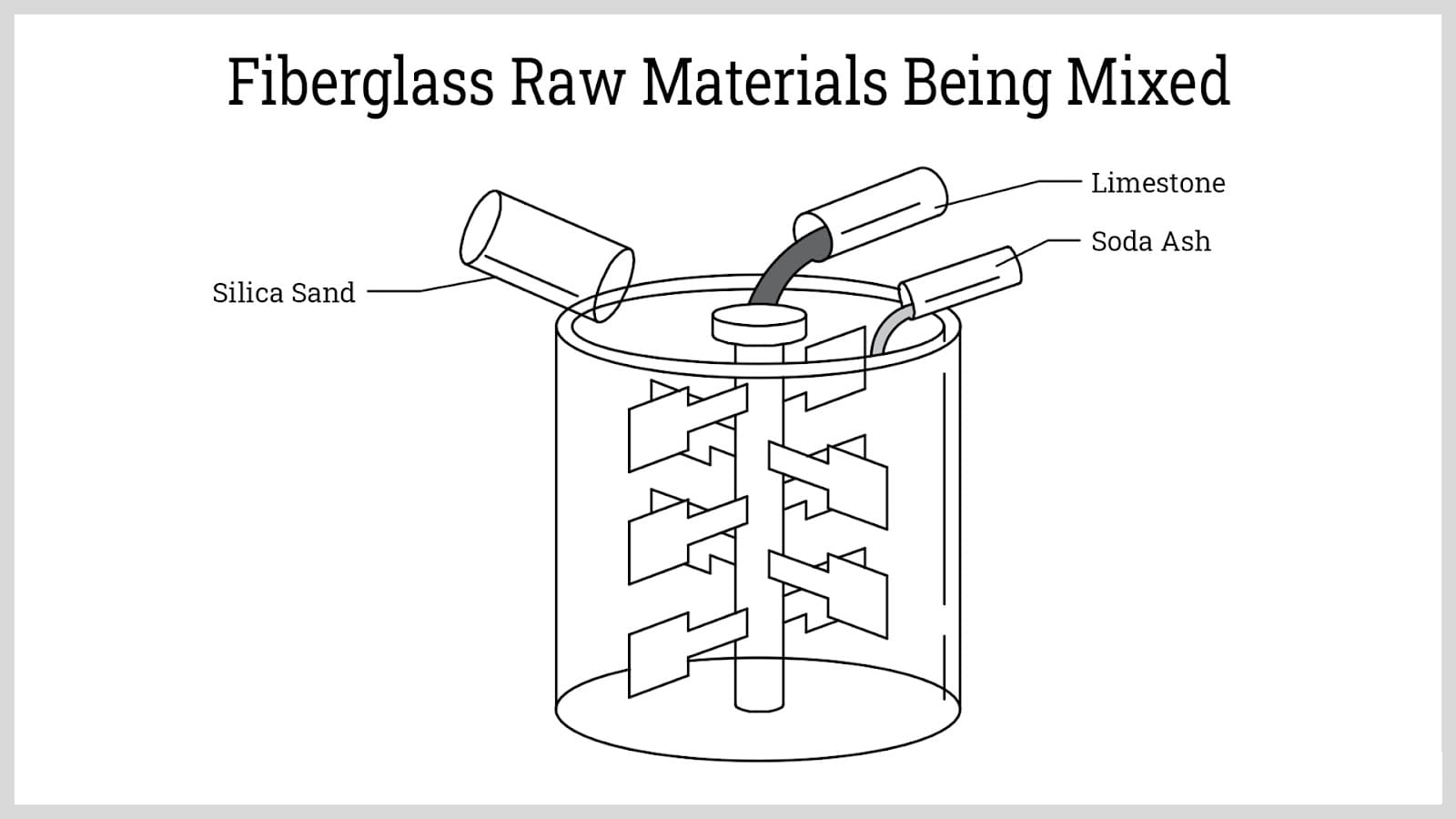

Raw Materials

The ingredients for fiberglass include silica sand, limestone, and soda ash. Added to those basic ingredients are calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay to name a few. The extra materials improve specific properties of fiberglass. The raw materials are carefully measured and mixed to form the batch.

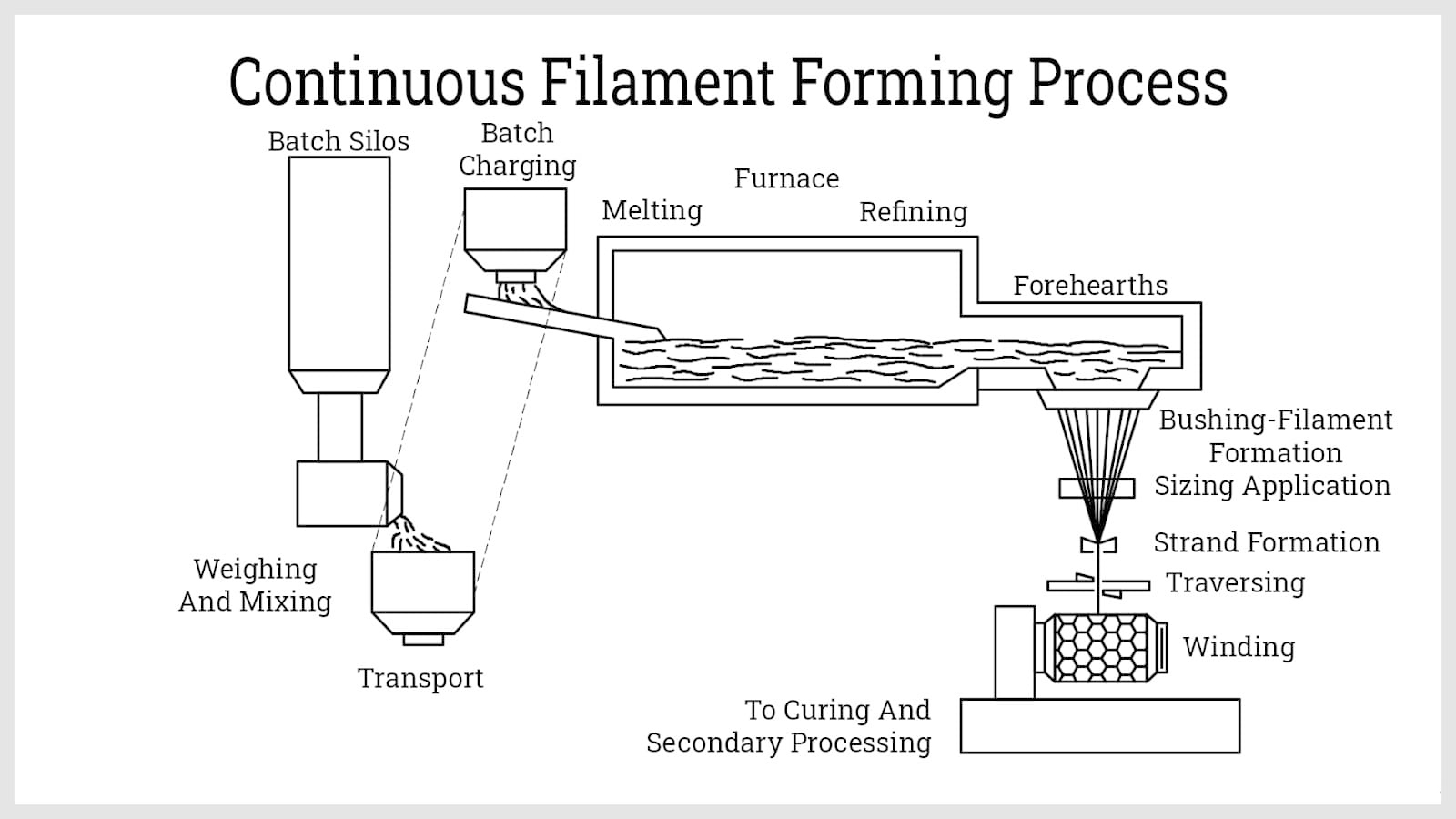

Melting

The mixed batch is fed into a furnace where it is melted. In order to produce a smooth even flow of glass, the temperature is carefully and precisely controlled. The molten mixture must be kept at 2500° F or 1371° C, which is higher than the temperature to form other types of glass.

Fiber Forming

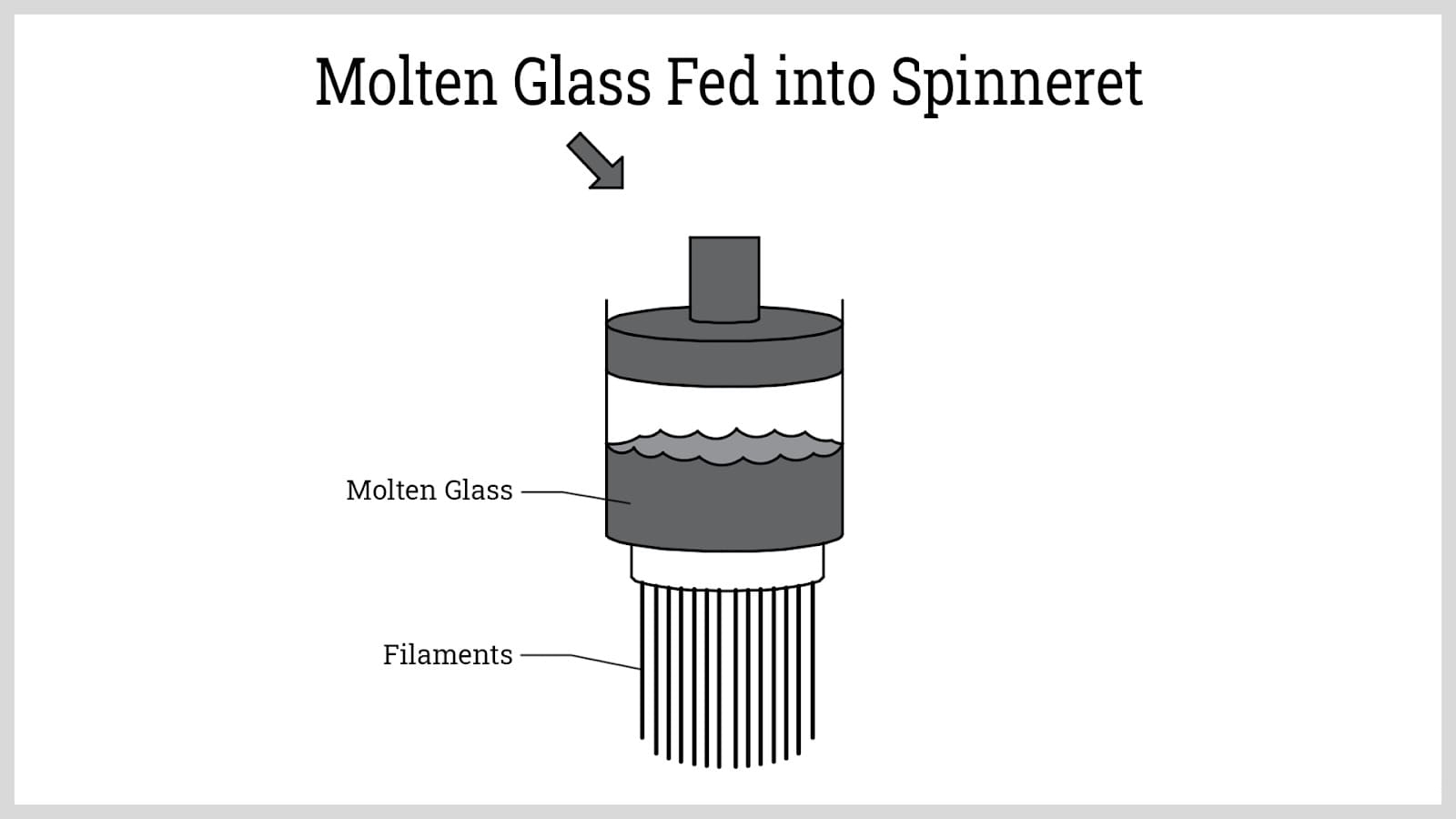

There are many different methods used for the forming of fiberglass fibers. Textile type fibers can be formed by taking the molten glass directly from the heating process. Marble fibers are formed by sending the molten glass into a marble forming machine. The newly formed marbles can be visually inspected for any impurities.

Regardless of whether the glass is marbles or texture, it is extruded through an electrically heated bushing known as a spinneret that has hundreds to thousands of openings through which the glass passes to become fine filaments. The openings on the bushing determine the diameter of the fiberglass fibers.

After the forming of the filaments, the process for finishing them falls into several different categories. Below is a brief description of a few of the methods used to process the filaments.

Continuous

After the glass leaves the bushing, the strands are caught in a high speed winder, which revolves at two miles a minute. The tension that is caused pulls out the filaments and forms strands that are a fraction of the holes in the bushing. During the winding process, a chemical is added as a binder to help keep the fibers from breaking during processing. The new filaments are wound around tubes to be twisted and plied into yarn.

Staple Fiber

In the staple fiber forming process, as the molten glass leaves the bushing, jets of cold air are applied to rapidly cool the fibers. The bursts of air have the added effect of breaking the filaments into various lengths. The filaments then fall through a spray of lubricant into a revolving drum, which forms them into a web from which it is pulled to form loosely assembled fibers to be processed into yarn.

Chopped Fiber

In the chopping process, the continuous strands are chopped into short lengths, mounted on bobbins or creels, and pulled through a machine that chops them into short pieces. The newly chopped fibers are formed into mats, have a binder applied, are cured in an oven, and rolled into mats.

Glass Wool

The creation of glass wool is created by a rotary or spinner process where the molten glass flows into a cylindrical container that has small holes on the side. As the cylinder spins, the molten glass exits through the holes. The stream of glass is subjected to blasts of either air, hot gas, or a combination thereof. Once they receive their bath of air and gas, they fall onto a conveyor, where they interlace to form a fleecy mass. The new configuration has a binder applied, is compressed, and cured in an oven to set the binder.

During the filament process, various binders are added to give cohesion to the glass fibers. Though the binder keeps the filaments and fibers together, it may not offer protection. For that purpose, some form of coating may be added.

Protective Coatings

When the binder is being applied, it may include a lubricant to reduce fiber abrasion. How it is applied depends on the manufacturing process. Another type of composition that can be applied during the cooling process is an anti-static compound, which penetrates the mass of fibers and serves as a corrosion inhibitor and stabilizer. At this stage of the process, a coupling agent may be applied if the fiberglass is to be used to reinforce plastics.

Chapter Four – Fiberglass Molding Processes

The determination of the process used to mold fiberglass depends on the type of part or component that is being created. The next consideration is the type of fiberglass material, which can be vinyl ester or polyester resin, fiberglass roving or matting, and gelcoat. Each of the different materials has their advantages depending on the application.

As with the production of fiberglass filaments, there isn‘t one single method for molding fiberglass. There are several factors that have to be considered when selecting a process. The molding process for commercial products varies greatly from the processes used for industrial applications.

Fiberglass Molding Processes

Plug

The plug, in the fiberglass molding process is a representation of the finished part, which can be the actual part, its representation, or a completely new form. The things that are considered when engineering the mold are surface finish, draft angles, undercuts, and production method.

An excellent surface finish begins with proper planning. Imperfections in the plug transfer directly to the final part. Every producer wants a class "A" finish, which is polished, high luster, and without porosity or scratches.

Release Agent

Though the plug is smooth and well formed, it will still adhere to the applied fiberglass during the molding process. To prevent this, a release agent is applied so that the final part can easily be lifted from the mold.

Fiberglass release agents, for industrial operations, are engineered to release the part efficiently and rapidly from the mold in a single step. Included in the release agent is a sealer that seals the substrate.

Gelcoat

Gelcoat is a specially formulated polyester resin designed to be applied as the first coat in a mold. It creates an opaque surface that is UV resistant. When the part is removed from the mold, the gelcoat is the exterior surface of the part. After the gelcoat is applied, the mold is cured.

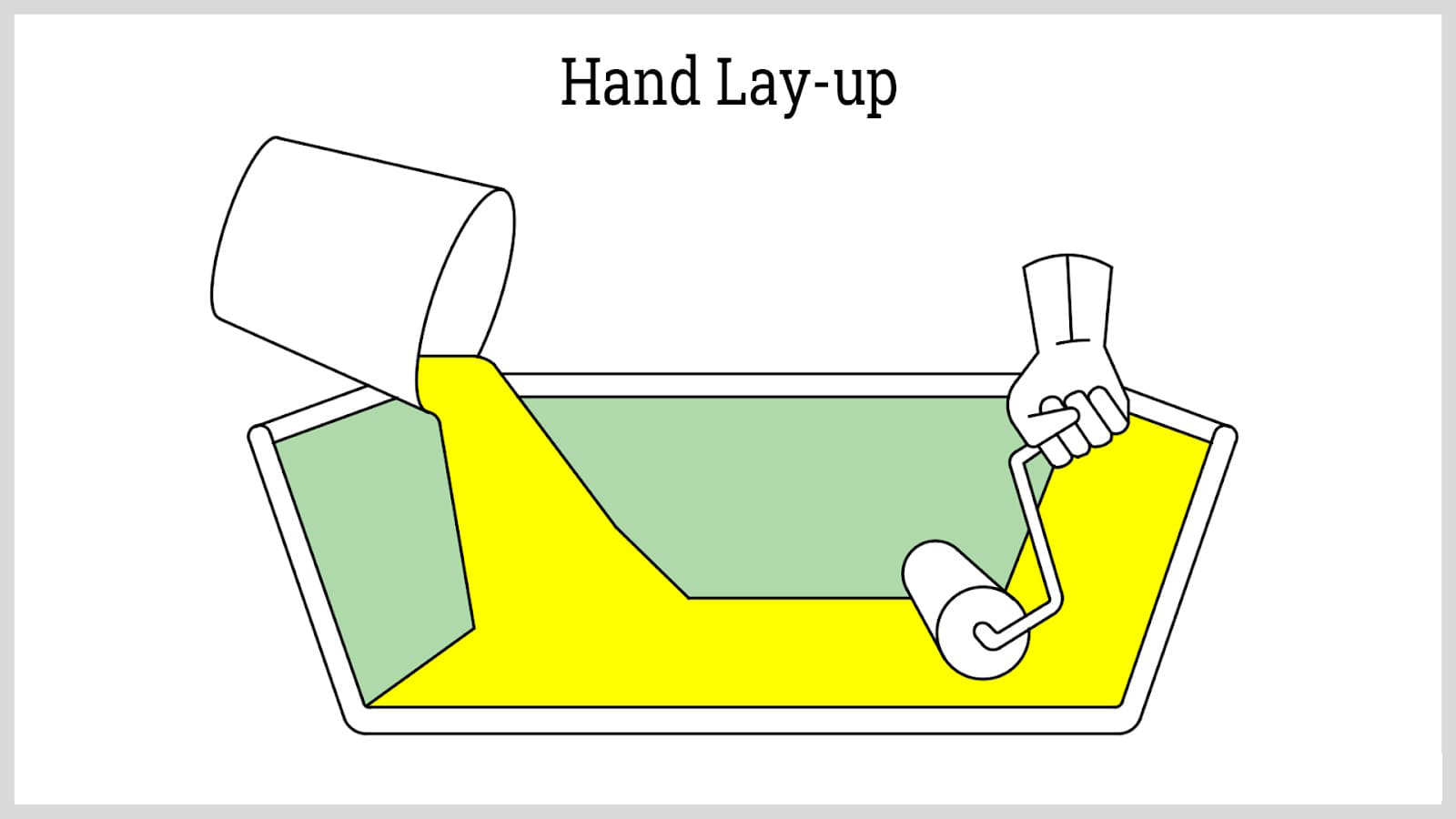

Open Molding

The open molding process involves a single sided mold that is the form and surface for the completed part. Gelcoat is applied to the mold surface before reinforcements are added. Resin and fiberglass can be sprayed into the mold or applied by hand onto the gelcoat. Layers of laminate are added to achieve the desired thickness for the final part.

An important step, once all of the materials have been added, is to remove any air pockets or air bubbles. This is completed by rolling over the mold. Once it is certain the mold is complete, it is cured.

Open molding is the most flexible of the fiberglass molding processes since there is a limitless number of sizes, designs, configurations, and components that can be produced using this method.

Closed Molding

There are a variety of types of closed molding processes, which include resin transfer molding (RTM), resin or vacuum infusion, and compression.

- Resin Transfer Molding (RTM) – RTM is a low pressure and temperature method of transferring a liquid resin into a closed mold through injection ports. The process is noted for its dimensional accuracy and high quality surfaces since the injected resin fills all of the voids in the mold impregnating the complete surface of the material.

- Resin Infusion – Resin infusion is a process where a vacuum is formed to pull resin into a dry fiber laminate in a one sided mold. The mold is sealed by placing a film membrane over the top to encapsulate the outside of the mold and cover the layers. The benefits of the process are less porosity of completed parts and exceptional casting strength.

- Compression Molding – For compression molding, the fiberglass material is compressed in a metal die using vertical force. As the pressure is applied the resin flows to fill the mold cavity. During the time that the mold is closed, the material undergoes curing that permanently hardens the molded shape in the mold cavity. The process can take several seconds or minutes to be completed.

Curing

Curing is the process of allowing the fiberglass mold time to toughen and harden. In general, it refers to a process whereby a liquid solidifies into a solid. The curing of fiberglass forms can be accomplished using several different methods. The simplest of the processes is to let the molded shape cure at room temperature after the application of a catalyst or hardening additive.

The curing process can be accelerated by applying heat through the use of an oven and pressure. The vacuum bagging process consolidates the various plies of the mold and removes any voids by off gassing.

Electron beam or E beam has been used by a few manufacturers for curing thin laminates. In E beam curing, the molded part is exposed to electrons that provides ionizing radiation, which causes crosslinking of resins.

Ultraviolet curing uses UV radiation to activate a photoinitiator that was added with the resin. When the UV rays strike the workpiece, the photoinitiator is activated setting off the crosslinking reaction.

An important part of curing is a careful monitoring of the process. The monitoring of the curing process involves gauging the conductivity of the ions in the resin material. The higher the viscosity of the resin, the slower is the movement of the ions.

Fire Ratings and Retardants

For certain applications, regulatory agencies require that all building materials be fire retardant and not act as fuel for increasing or prolonging a fire. Though fiberglass is incombustible, the resin in it is highly flammable and has to be coated to prevent it from increasing the spread of a fire. Resins will burn when supported by an outside source. There are several forms of flame control and flame retardant coatings designed to meet federal, state, and local building and fire codes that are applied during the production process.

Building materials are traditionally tested using the American Society for Testing and Material E-84 test (ASTM E-84). The purpose of the ASTM E-84 test is to observe the spread of flames on a sample of building material and its burning behavior. The resulting report from the test includes a flame spread index (FSI) and a smoke developed index (FDI). The information garnered from the test is used to Classify materials as A, B, C, D, or E.

One form of fiberglass coating retards the spread of fire and reduces heat through the use of intumescent technology, a process where a material swells and chars to protect the material underneath it. Referred to as intumescent flame retardant (IFR), it is an eco-friendly flame retardant with high efficiency and low smoke and toxicity. IFR contains aluminum oxide, silicon oxide, and various other metal oxides.

Fire retardant paint coatings react to increased heat by releasing a flame dampening gas that delays the spread of fire. The delay time provides the opportunity to extinguish the fire. Its use is extremely effective in suppressing the reaction of fire to fiberglass and has an ASTM E-84 class A rating, meaning fire spreads very slowly where fire retardant paint is present and can withstand severe fire exposure.

Chapter Five – Benefits of Using Fiberglass Molded Parts

Of the many fabricating materials, fiberglass is the most popular for reinforcing and stabilizing polymers due to its many positive properties. The initial use of fiberglass was for a supplement for plywood in the building of aircraft during World War II. From that initial use as a strong fabric for aircraft design, it has migrated into a wide variety of industries due to its strength, cost effectiveness, and ease of fabricating.

Benefits of Using Fiberglass Molded Parts

Tensile Strength

Fiberglass produced parts have the same strength as steel with only one fourth the density, which reduces the weight of the finished part. The very high MPa rating of fiberglass ensures its excellent rigidity making it ideal for construction projects where great strength is required.

The obvious strength of fiberglass can be exemplified in its use in the manufacture of bridges, balconies, the facades of buildings, and platforms. It has a high strength to weight ratio that has made it an ideal product for gratings that have to carry vehicular loads.

Non-Conductivity

Fiberglass is a good insulation material even at low thicknesses. The glass and resin used to make fiberglass are not electrical conductors since they do not contain metals and do not have any free electrons.

Incombustibility

Incombustibility refers to a product or parts ability to burn. Fiberglass is made up of mineral materials, which are naturally incombustible and do not support or produce any form of flames. When heated, fiberglass does not produce smoke or other toxic products.

Dimensional Stability

Dimensional stability is critical for parts since maintaining their original shape and size is an essential necessity for their use. Since fiberglass is not sensitive to changes in temperature and hygrometry, vapor or water in the air, and has a low coefficient for linear expansion, it is capable of retaining its original shape and configuration in the harshest of conditions.

Thermal Conductivity

Thermal conductivity, the transference of heat, is a critical factor when considering building materials. A reason that fiberglass has become an essential part of the construction is this single property. Fiberglass has low thermal conductivity. It will not burn, is unaffected by curing temperatures, and retains 50% of its strength at 700°F and 25% at 1000°F.

Chemical Resistance

A major reason that fiberglass has become so widely used is its ability to resist any form of substance that may cause rot or decay. It is resistant to the effects of continually being exposed to water and is unaffected by acids with the exception of hydrofluoric and phosphoric acids.

Dielectric Permeability

Much like nonconductivity, materials with dielectric properties do not allow electric currents to pass through and are the complete opposite of an electrical conductor. This particular characteristic of fiberglass makes it ideal for mechanisms that require protection from electromagnetic fields (EMF).

Durability

Aside from its exceptional tensile strength, fiberglass is very durable since it does not rot, corrode, or is susceptible to rust. This feature ensures the integrity and longevity of parts and materials produced from it. Fiberglass is built to endure any form of tough, rigorous, and harsh treatment and is normally chosen for conditions where there are corrosive substances or materials.

Lightweight

Regardless of the fact that fiberglass has the strength of steel, it weighs far less, at least a fourth of the weight of steel. This particular feature added to its dimensional stability enhances its use since it is long lasting. The lighter weight adds to its ease of installation and ability to be designed to fit any configuration.

A negative aspect of heavy weight materials is the increased cost associated with installation. The cranes, lifts, and other equipment required to install heavy materials are not needed for the installation of fiberglass.

Maintenance

Associated with fiberglass‘ durability is its low maintenance, which significantly lowers the overall cost of its use. During the life of a fiberglass part, there is little need for painting, chemical cleaning, or other means of maintenance.

Design Freedom

Any number of products are made from fiberglass since its flexibility gives designers the chance to take what they envision into reality. From broom handles to electrical enclosures and car doors and fenders, fiberglass can be molded, shaped, and configured to fit the needs of any product.

Soundproofing

Different varieties of fiberglass are ideal for sound proof. The NRC rating is the determining factor regarding which types meet soundproofing specifications. The higher the NRC rating, the greater the ability of the fiberglass to absorb sound. Fiberglass insulation that is 3.5 inches thick has a NRC rating of 0.9 to 0.95, which makes it ideal for soundproofing.

Biological Resistance

There are many biological and environmental factors that can influence the lifespan of a product. Fiberglass is a long lasting material that is resistant to the effects of environmental contamination as well as microorganisms. In most cases, once it is installed, it is most likely going to last the full life of an application.

Included in the biological resistance of fiberglass is its inability to absorb other materials such as water, which causes other types of fabrics to rot.

Insensitive to UltraViolet (UV) Radiation

Ultraviolet degradation is a form of photo corrosion that is caused by light with minute wavelengths between 10 to 400 nanometers (NM). These sizes of UV rays are not visible to the naked eye but cause harm to textiles, wood, certain types of steel, aluminum, and polymers. The resulting effects are inconsistencies and the acceleration of corrosion.

Fiberglass is treated with various forms of coatings that prevent the effects of UV degradation and assists in maintaining the integrity and strength of the fibers.

Chapter Six – Types of Fiberglass

Fiberglass can be fabricated to fit specific uses. Each type varies in composition resulting in distinct and unique characteristics. Regardless of the different types of fiberglass, the basic composition of fiberglass is pretty much the same with the exception of certain raw materials.

It is the amount of raw materials in each type that creates the distinction between the types. From the basic materials of silica sand, soda ash, and limestone, borax, calcined alumina, magnesite, kaolin clay, and feldspar can be added to change the characteristics and properties of the fiberglass.

The division of fiberglass into the various types is determined by its properties and characteristics. The addition of one raw material may enhance the chemical resistance of the fiberglass, while the addition of another may produce a fiberglass for cookware.

Types of Fiberglass

A-Glass

A-glass is the most common of the fiberglass materials and is known as alkali or soda lime glass. Approximately 90% of the glass that is produced is alkali glass, which is used to produce jars, bottles, and windows. It is chemically stable, inexpensive, highly workable, and hard. One characteristic that makes it popular is its ability to be re-melted and softened numerous times.

The two types of A-glass are flat glass and container glass, while flat glass is produced using the float process container glass is made by the blow method. The difference between the two is the quantity and mixture of raw materials.

C-Glass

C-glass, known as chemical glass, is resistant to the influence of chemicals and provides protection in corrosive conditions. This particular characteristic is due to the high amount of calcium borosilicate that it contains. C-glass is used as a laminate much like surface tissue for pipes and tanks that hold water and chemicals.

D-Glass

D-glass fiberglass is known for having the property of low dielectric constant due to the use of boron trioxide in its composition. This one property makes it ideal for use in the manufacture of optical cables. The inclusion of borosilicate gives this form of fiberglass a low coefficient for thermal expansion. The use of boron trioxide and borosilicate makes D-glass fiberglass perfect for the production of electrical appliances and cookware.

E-Glass

The "E" in E-glass fiberglass stands for electrical glass, which is lightweight and used in the manufacture of parts and equipment for aerospace, marine, and various forms of industrial applications. It has excellent draping qualities that makes it easy to clean and work with.

Though E-glass fiberglass was developed to be used with electrical applications, it has found use in many other areas. One of its main uses is as a reinforcement for plastics made with a thermosetting resin. This form of material is strong and sturdy enough to form a protection against mechanical impact.

HR-Glass

HR-glass has an extremely high thermal resistance of up to 800o C. It is an aluminosilicate that can be substituted for E-glass due to its high temperature resistance.

Advantex Glass Fibers

Advantex glass is formed by combining E-glass with ECR glass. This type of fiber has the same corrosion resistance as ECR glass but at the cost of E-glass. It is ideal for conditions where there are thermal fluctuations since it has a higher melting point. Advantex fiberglass is used in the oil, gas, and mining industries as well as sewage and wastewater management.

ECR Glass

The term ECR glass refers to electronic glass fiber, which has mechanical strength, waterproofing capabilities, and alkali and acid corrosion resistance. ECR glass is made using calcium aluminosilicates that gives it strength, resistance to acids, and electrical conductivity. Its durability is due to its resistance to acids, water, and alkali. Regardless of its many positive properties, it has a lower cost than other fiberglass materials.

AR-Glass

The AR in AR-glass stands for alkali resistant glass that has been developed to be used in concrete with a composition that includes Zirconia, a material that is essential for the production of hard ceramics. The purpose of AR-glass being added to concrete is to enhance the concrete‘s strength and flexibility. It is difficult to dissolve it in water and is unaffected by changes in pH.

R, S, and T-Glass

These three forms of fiberglass are stronger and have greater tensile strength than E-glass as well as having better wetting properties and acidic strength. This group of properties are the result of reducing the diameter of the fiberglass filaments. The purpose of R, S, and T-glass is for military and aerospace industries as well as having value as a rigid ballistic armor. This type of fiberglass has higher cost because its being developed for use with a small group of specialized industries.

S2-Glass

S2-glass is the highest quality of fiberglass and has a higher level of silica content, which enhances its weight, temperature resistance, compressive strength, and impact resistance. One of the main benefits of S2-glass is its high tensile strength, which is 85% stronger than any other form of fiberglass. Its fiber content makes it tougher and modulus for improved impact resistance resulting in less damage and increased durability.

SiO₂-Glass

SiO₂-glass has an exceptionally high temperature resistance of over 1000° C. It is a long lasting fiberglass due to its high temperature resistance that keeps it from vaporizing or melting. The molecular structure of SiO₂-glass, which is tetrahedral and amorphous, meaning it does not have a crystalline structure, makes a unique form and new generation of fiberglass.

M-Glass

M-glass fibers are very strong and able to withstand high pressure and impact. This type of fiberglass is made with reinforced fiber plastic that is silicone treated to enhance its durability. M-glass has greater dimensional stability compared to other fiberglass fabrics due to its densely aligned fibers, which enhances its strength but not its weight. A special feature of M-glass is the addition of beryllium, a compound that gives it increased elasticity.

Z-Glass

Z-glass has exceptional mechanical properties and is resistant to UV rays, acids, alkali, salts, and is scratch, wear, and temperature resistant. It is one of the more durable and reliable of the different types of fiberglass. Z-glass is semi transparent and can have 3D printing applied. It is an excellent replacement for brittle glass and is used for prototyping for designs in the auto industry.

Forms of Fiberglass

Tow and Roving Fiberglass

Fiberglass in this form has the highest properties of all fiberglass. It is delivered in spools to be fed into filament winders or cut for stiffening. When being stored, it has to be kept in tension or it loses its mechanical properties.

Veil Mats

Veil mats are thin continuous strands of fiber looped throughout a roll with a tissue type of consistency. The fiberglass has a light binder that keeps it together. This form of fiberglass is not intended for structural functions but can be placed directly in a mold behind the surface coating.

Chopped Strand Mat

Fibers for chopped and strand matting are a few inches in length and are haphazardly placed. This form of mat is not very strong. The one beneficial factor is that it is equally strong in all directions, or isotropic. It is the least expensive, most widely used, and is suitable for mold production.

Woven Fabric

The fibers in woven fabric are anisotropic or oriented in two directions and are bundled like yarn, which results in the fabric being very strong. The fabric has to be placed such that it runs parallel to the load. When extra strength is needed in another direction, extra fabric has to be added.

There are many different types of woven fabric with a plain weave being the most common but the least pliable. Twill weaves and satin fabrics are more pliable and have greater strength than plain weaves. Since these weaves are more pliable, they comply easily to complex shapes and designs.

Chapter Seven – Industrial Use of Fiberglass Molding

When it was discovered that fiberglass, when added to a resin, becomes stronger and more durable, it became an essential part of the manufacturing processes of several industries. The reason that fiberglass is so widely used is it being inexpensive, resistant to violent impact, corrosion and chemical resistant, and its exceptional strength to weight ratio.

The number of industries that rely on fiberglass could fill a book. Listed below are a few industrial operations that have fiberglass as a vital resource to the production of their products.

Industrial Use of Fiberglass Molding

Boat Building

From the hull to decks, tables, and chairs, most of the parts of a boat are made from fiberglass. Since it was first used to shape a boat in 1942 and with the development of more stable resins and production methods, boat manufacturers have relied on fiberglass as the perfect method for producing their products. Other materials such as wood, aluminum, and steel are more difficult to shape and more expensive making fiberglass the ideal solution.

Home Furnishings

Much like the industries that use fiberglass, the list of items made of fiberglass for the home is endless and includes door frames, window frames, shower stalls, bathtubs, swimming pools, hot tubs, and a wide array of other items, which can include kitchen sinks and appliances. The development of items for the home using fiberglass has expanded the resources for the home furnishing industry.

Amusement Park Attractions

Without the development of fiberglass, water parks would not exist. The slides, troughs, and funnels are all made of easy to form and shape fiberglass. The rocks and facades of theme park attractions are made from molded and formed fiberglass that is either made off property or in the back areas. Every amusement park has a specialist that has the skill to repair damage to any of the many attractions.

Electronics

The many electronics devices that we use rely on circuit boards made from fiberglass. The fact that fiberglass is lightweight makes it ideal for use in laptops, computers, and cell phones. Like home furnishings, fiberglass is found in all of the electronic components in a home.

Automotive industry

The first car body made completely out of fiberglass was introduced in 1953. At the time, the design did not prove to be as efficient and applicable to auto production. Since that first venture, and the need for fuel economy, fiberglass has become a central part in the planning and design of automobiles.

The fact that fiberglass can be shaped and configured into any form has offered automobile designers a flexible tool for producing unique and intricate designs. Custom and replacement parts can be easily reproduced as well as the creation of old designs.

Another major benefit is the lower cost of tooling since metal presses are far more expensive to operate. The production of fiberglass parts is quicker, more efficient, and produces more durable parts, a necessity in the modern market.

Aircraft and Aerospace

A requirement of any part of an aircraft is sturdiness, durability, and being lightweight. To meet the stipulations of the aerospace industry, S-glass, with its high strength to weight ratio, has become an ideal material for the construction of aircraft. One of the major concerns for any product used in aircraft is the ability to withstand the necessary stress. S-glass has been found to have a high fatigue life and the ability to retain its dimensions at higher temperatures.

Added features of S-glass fiberglass are its exceptional mechanical strength and nonconductivity. An ideal feature for military aircraft is its low radar thermal profile, which offers a tactical advantage.

Construction

The property of dimensional stability is a major factor in the choice of fiberglass in the construction industry as well as its incombustibility, lightweight, impact resistance, long life, and superior strength. The versatility of fiberglass allows it to be used as an exterior finish and interior material for achieving various designs. Fences, skylights, swimming pools, solar heating, fixtures, railings, stairs, and platforms can all be made of sturdy fiberglass.

Chapter Eight – Safety Concerns for Fiberglass Molding

Fiberglass, known as glass wool, fibrous glass, and glass fibers, is made up of extremely tiny fibers of glass and chemicals. When it is being sanded, cut, chopped, or trimmed, it produces harmful dust that contains fibers that can get on the skin and into the eyes, which places workers at a health risk.

Producers of fiberglass products are well aware of the hazards involved in the production of their products and take extreme measures to ensure the safety and wellbeing of their workforce. This one factor is a major concern.

Additionally, the office of the Occupational Safety and Health Administration has developed guidelines regarding the handling and production of fiberglass. The Environmental Protection Agency (EPA) has regulations regarding the installation and use of fiberglass products as well as the pollutants produced during production.

Safety Concerns for Fiberglass Molding

Fiberglass Hazards

Large fiberglass fibers irritate the skin, eyes, and can get into the upper respiratory tract of workers. Exposure to fiberglass can lead to serious health conditions and risk. Constant exposure to fiberglass by unprotected skin leads to irritation and rash, while inhaling fiberglass dust irritates the nose, throat, and breathing passages.

A more serious condition can occur if fiberglass dust is swallowed. In this case, the fibers cause irritation to the stomach. When inhaled, fiberglass dust settles in the lower part of lungs and causes constant irritation and breathing problems.

Protective Gear

Due to the many hazards related to handling fiberglass, employers supply employees with inspected and approved safety gear. As with all manufacturing, the first thing employees wear are safety glasses to protect their eyes. For greater protection, goggles are used to completely enclose the eyes. Additionally, various types of masks are used that cover the nose and mouth. This form of safety device is made of heavy material and prevents any form of particles entering airways.

Another standard piece of equipment is a pair of gloves that are designed to prevent fiberglass particles from getting on the hands. Normally, this type of glove extends up the arm to the elbow and covers the forearm.

Workers that continually work with fiberglass have more rigorous protective gear, which covers the head and neck. The front of the head gear has a respirator with interchangeable air filters.

Included in the protective gear provided by employers is protective clothing usually in the form of a jump suit that covers workers from the neck to their ankles. The fabric in the clothing is designed to prevent the passage of dust particles and is made with a very fine weave of resilient material.

First Aid Measures

In all work areas used for fiberglass production is an eye washing fountain with two jets of water. For further protection, manufacturers supply employees with showers and areas for regular hand washing.

Occupational Safety and Health Administration (OSHA)

There are several sections of the OSHA regulations that address the concerns for workers who come in contact with fiberglass dust.

General Industry 29 CFR 1910 – This regulation relates to dust from synthetic fibers.

Health Effects – OSHA has published a list of the health effects that can occur due to exposure to synthetic fibers. Their research includes data from several national and world organizations.

Exposure Limits – The information in regard to this aspect of production covers all forms of chemicals including synthetic fibers and has specifics regarding each form of toxic material.

OSHA No. 2005-149 - Provides descriptions regarding exposure limits, methods of measurement, protection and sanitation methods, first aid, recommendations for respiratory concerns, symptoms, targeted organs, and where cancer may develop.

OSHA also provides data regarding the appropriate protective gear, how to protect a worker‘s lungs, and what types of materials are carcinogenic.

Standard 1926.957 – This standard is specifically written for the construction industry and its use of fiberglass.

Environmental Protection Agency (EPA)

The EPA provides information regarding the types of pollutants produced by fiberglass fabrication, methods to reduce pollutants, and the resources available for reducing fiberglass pollutants.

Conclusion

- Fiberglass molding is a method for forming complex and intricate parts using fiberglass resin.

- Fiberglass molding is an inexpensive method for the production of durable and lasting products and parts.

- From its original discovery to be used as insulation, fiberglass has grown into a widely used material that can be shaped into limitless products.

- The ingredients for fiberglass include silica sand, limestone, and soda ash. Added to those basic ingredients are calcined alumina, borax, feldspar, nepheline syenite, magnesite, and kaolin clay to name a few.

- The determination of the process used to mold fiberglass depends on the type of part or component that is being created.