Electronic Connector Manufacture Solution

Electronic connectors are a crucial component in electronic devices, enabling the transfer of power and data. At V1 Mold Technology, we specialize in manufacturing high-quality electronic connectors using advanced injection molding techniques. Our team has extensive experience in designing and producing a wide range of electronic connectors for various industries, including automotive, telecommunications, and consumer electronics. We can also provide customized solutions to meet specific customer requirements.

Precision Molding for a Wide Range of Electronic Components

At V1 Mold, we specialize in creating high-precision, in-house molds for a wide range of electronic components. With our experience and expertise, we’ve successfully contributed to the development and mass production of various products, including control panels, consumer electronics, electronic connectors, and enclosures. Trust us to deliver efficient and cost-effective solutions tailored to your specific needs.

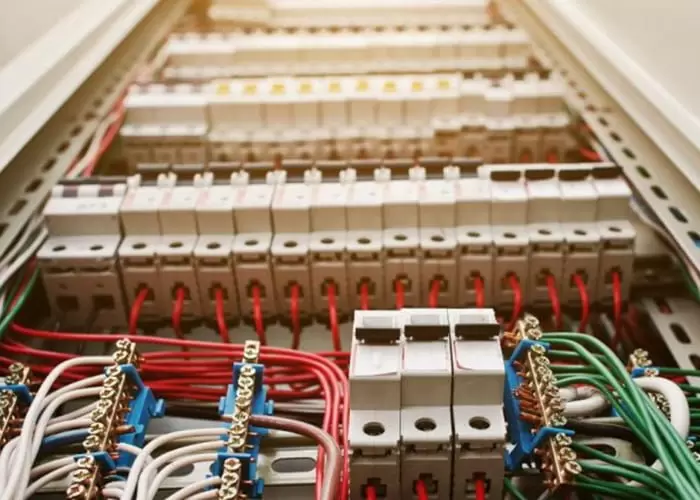

Control panels

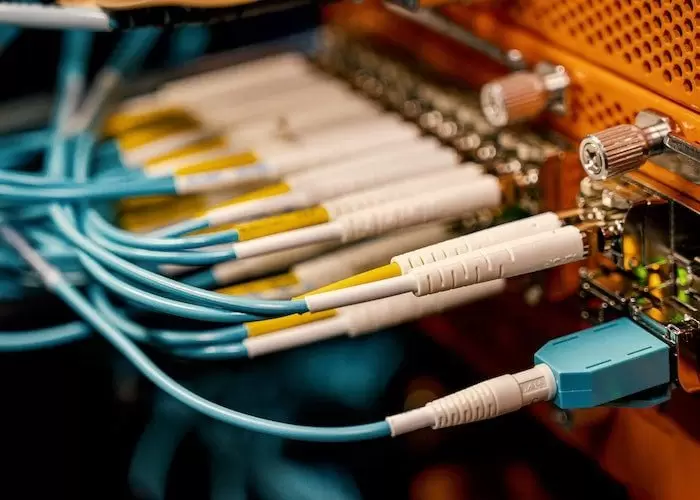

Consumer electronics

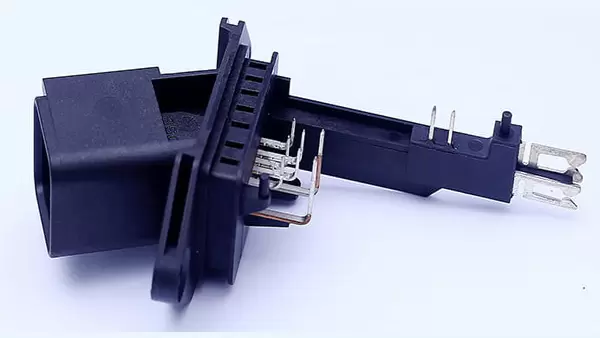

Electronic Connectors

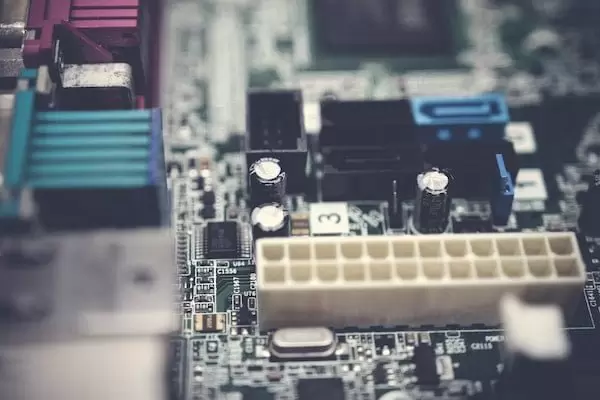

Electronic enclosures

V1 Electronic Connector Manufacture services

Our electronic connector manufacturing process involves using high-precision molds and equipment to ensure consistent quality and accuracy. We also use only the highest quality materials to ensure that our connectors are durable and reliable. Additionally, we are committed to providing excellent customer service and timely delivery to ensure customer satisfaction.

Expertise in Electronics and Electrical Tooling Manufacturing

The Electronics & Electrical Tooling Factory at v1 has extensive industry experience, and we understand the manufacturing standards that must be followed to ensure that the plastic parts developed are efficient, safe, and long-lasting.

At V1 Mold, we strive to deliver high-quality products with short lead times and low manufacturing costs.

To ensure that the standards are met, we develop validation protocols, testing procedures, and process improvement studies. Furthermore, we have a diverse set of suppliers for specific components. In this case, the customer requires specific components to assemble their products, such as PCB boards.

V1's Electronics & Electrical Injection Molding Gallery

Explore V1 Mold's extensive gallery of high-quality electronics and electrical injection molding products. Our experienced team ensures that each product meets industry standards for efficiency, safety, and longevity. From custom PCB boards to intricate plastic components, we offer solutions tailored to your specific needs.

High-Precision Electronic Component Manufacturing

V1 Mold specializes in high-precision electronic component manufacturing using advanced molding techniques. Our team has extensive experience in designing and producing small precision molds with tight tolerances up to 20 mm in size. We work with leading electronic companies to create high-quality products that deliver exceptional results. Our expertise in inserts and overmoldings allows us to assist you in the production of electronic and electrical components at various stages and levels of complexity.

Protecting Your IP with V1

At V1 Mold, we value the importance of intellectual property in the electronics industry. As a wholly owned subsidiary of the V1 Group, we prioritize the confidentiality of our clients’ intellectual property. We have established confidentiality agreements with all of our clients to ensure that their proprietary information is kept safe and secure.

In addition to confidentiality agreements, we have established design facilities and an IT department to further protect our clients’ intellectual property. With these measures in place, our clients can trust that their sensitive information is secure with us.

Compliance with ISO 9001:2015 in V1 Mold's Electronics Industry

Our factories are all ISO 9001:2015 certified. Our manufacturing plants adapt their capacities to the needs and requirements of our customers.