V1 Technical Capability

V1 provides leading-edge injection moulding services, but our expertise extends throughout the entire manufacturing process – from design to delivery, and everything in between.

Design Capabilities

At V1, Our team of engineers will assist you in developing a clear understanding of your requirements and help you make important decisions that will speed your design to mass production. V1 engineers always do their best to consider every point in mold design stage to avoid losing for future modification in plastic production.

CAD / CAM Softwarev

- AUTOCAD 2007

- UG NX8.5 CAD

- UG NX8.5 CAM

- Pro-e Wildfire Version 5.0

- Autodesk Simulation

- Moldflow Insight 2015

Design Engineering Capabilities

At V1 MOLD, there is a Project Manager and a Project Engineer assigned for every project . is successfully completed.

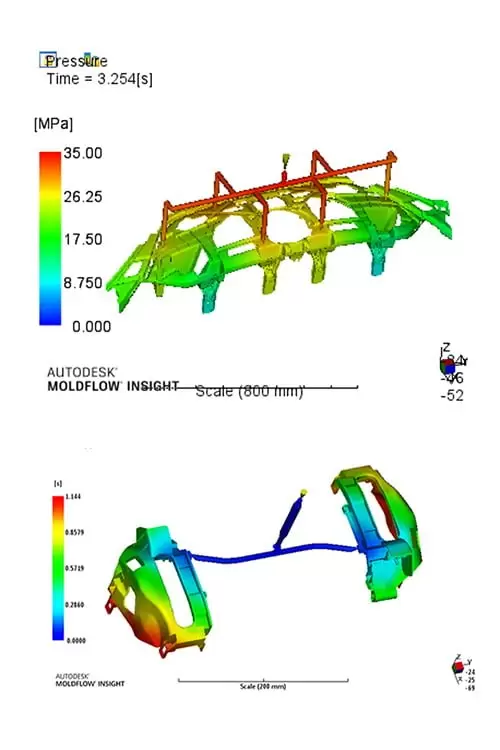

DFM & Mold flow

Submit DFM report and mold flow report

Mold Design

Submit 3D/2D mold drawing

Design Validation

Validate by V1 check list Control cation plan Validate by customer

Tolerance Analysis & Steel safety

Study the tolerance and mold flow to modify the mold drawing accordingly and ensure the steel

Steel Ordering

Approval to order steel & Approval to Start milling

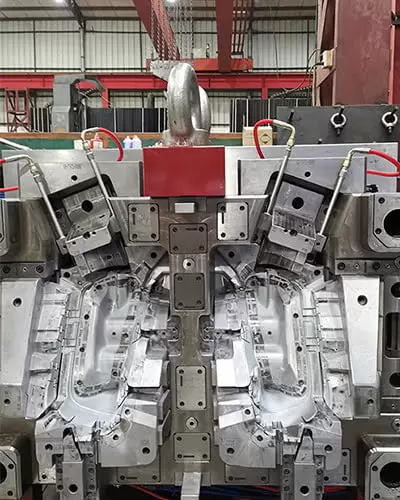

Mold Type

Innovative, workable prototypes & design solutions inform and enhance the quality of our work, ensuring value for money and full customer satisfaction.

Plates and Mold Base Components: ± 0.013 mm (± 0.0005 in)Cavity components: ± 0.005 mm (± 0.0002 in)

Tolerances

- Prototype Mold

- Insert Mold/Over Mold

- Multi-Cavity Mold

- 2K/3K Mold

- Reverse Mold

- Automated Unscrewing Mold

- Stack Mold

- Gas Assisted Mold

Mold-flow

Standardized production and business processes make molds more worry-free

V1 Developing Flow Chart

- Customer Reguest

- Purchase Order (PO)

- Mould Design

- Mold Manufacturing

- Mold Trial

- Shipping

- After Sales Service